Sheets used for blister packaging are called hard films or films. Commonly used are PET (polyethylene terephthalate) hard films, PVC (polyvinyl chloride) hard films, and hard films. PS hard film has low density, poor toughness, easy to burn, and styrene gas (belonging to harmful gas) will be generated during burning, so it is generally used to produce plastic trays for various industries. PVC hard film has moderate toughness and is not easy to burn. Chlorine gas will be generated during combustion, which will have certain impact on the environment. PVC is easy to heat seal. It can be sealed with a sealing machine and a high-frequency machine. PET hard film has good toughness, high transparency, easy to burn, and does not produce harmful gases during combustion. It is an environmentally friendly material, but the price is high. It is suitable for high-end plastic products. Blister shells in European and American countries generally require PET hard film It is not easy to heat seal, which brings great difficulties to packaging. In order to solve this problem, people compound a layer of PVC film on the surface of PET, named PETG hard film, but the price is higher.

We have 50 to 100 employees, and the annual sales volume has exceed USD$5,000,000 at the moment. 80% of our products are exported to worldwide.

We have modern mold making machines. We had passed the UKAS ISO9001:2000 quality system certification. In addition, we also have excellent designers,We specialize in the design and production of high quality thermoformed packaging. Outstanding management team and advanced control system. We can offer OEM service, except our current product range. When contacting us you will speak to a knowledgeable thermoforming expert and receive a quote within 24 hours. We have no reps or middlemen. You’ll get a straight answer and a competitive price. “Superior quality, reasonable price, punctual creation” is our principle.

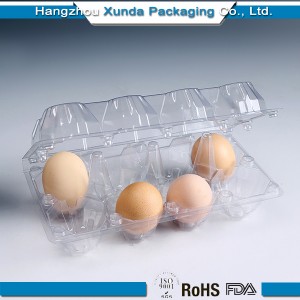

Xunda Clamshell Packaging, Your Clear Plastic Packaging Manufacturer. If you are interested in our products. Please feel free to contact us. We are looking forward to building business relationship with customers worldwide.